SPECIALIST AUTOMOTIVE AND MOTORSPORT ENGINES & SERVICES

Established in 1972 Nicholson McLaren Engines Ltd is a name that is engraved in Motorsports history.

Based in Berkshire, United Kingdom we have the capability of carrying out engine development, engine rebuilds, component design, precision engineering, manufacturing, engine benchmarking and bespoke testing programs for both Aviation and Automotive.

In house, we have facilities to support all aspects of an engine build and we are proud to offer our engine development services using one of our 2 x engine dynamometers or by running your car in our dedicated 4×4 hub dynamometer test cell.

We have state of the art scanning capability and the skills required for reverse engineer components or for repairing those obsolete parts.

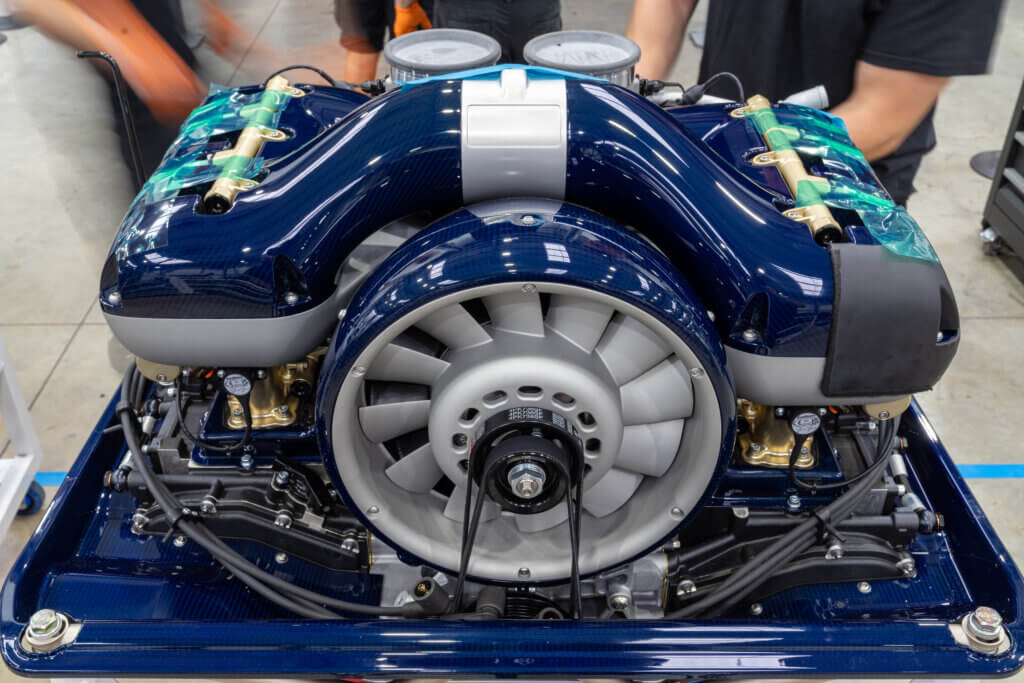

Our team of engineers are experienced in working on a diverse range of engine types that include (but not limited to) Cosworth, Jaguar, Porsche, Nissan, Buick, Matra & Ford – and on the aviation side Lycoming and Continental amongst other components.

The engineers at Nicholson McLaren are professional in their field of expertise, they only apply the highest standards of care and precision to your engine for optimum performance and reliability.

Nicholson McLaren & Singer Vehicle Design

Read the interview with CEO John Waghorn about powering Singer cars.