Nicholson McLaren Engines has an enviable reputation in the engine building sector, a fact that has resulted in many partnerships and technical collaborations in the past – not to mention some very big name formula 1 and manufacturer & privateer race teams around the globe.

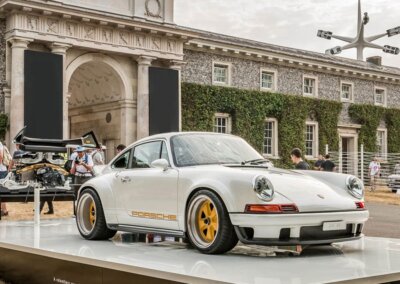

For the past few years Nicholson McLaren Engines has been working on an engine development program, firstly with Williams, then with Singer Vehicle Design – the company renowned for their restomod based Porsche 911’s built to customer specification.

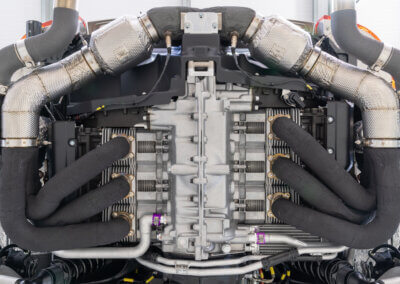

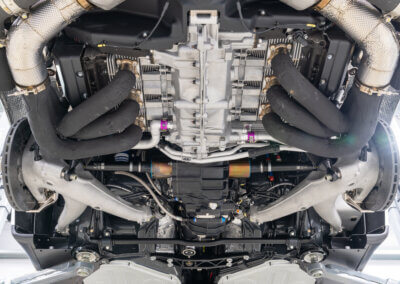

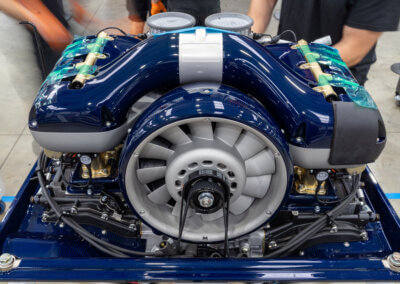

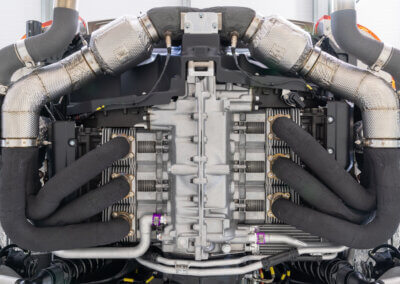

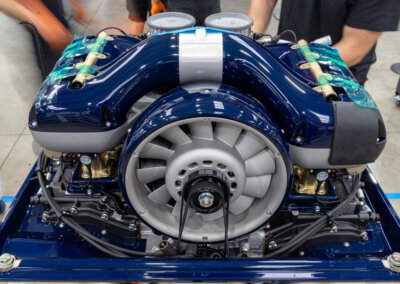

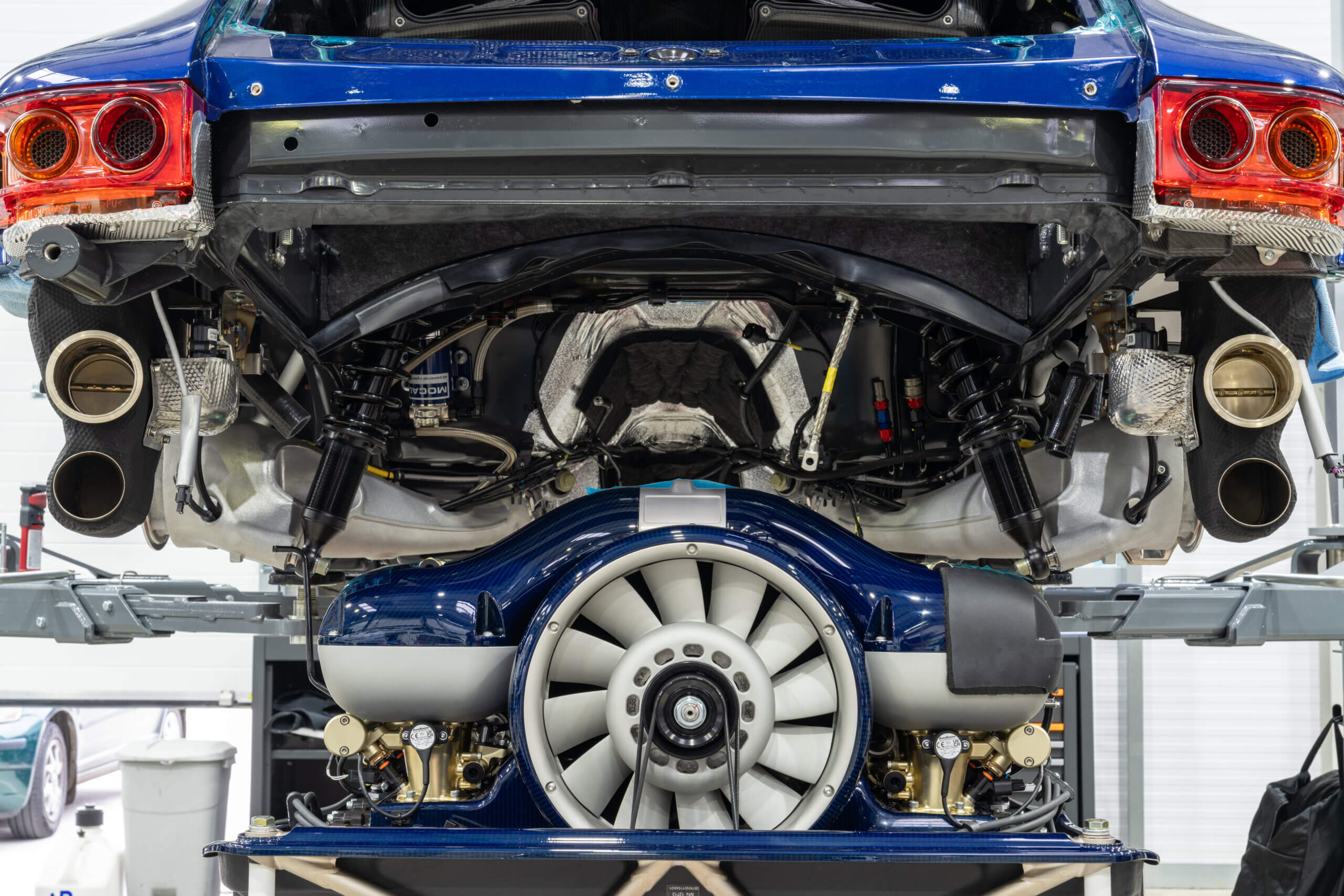

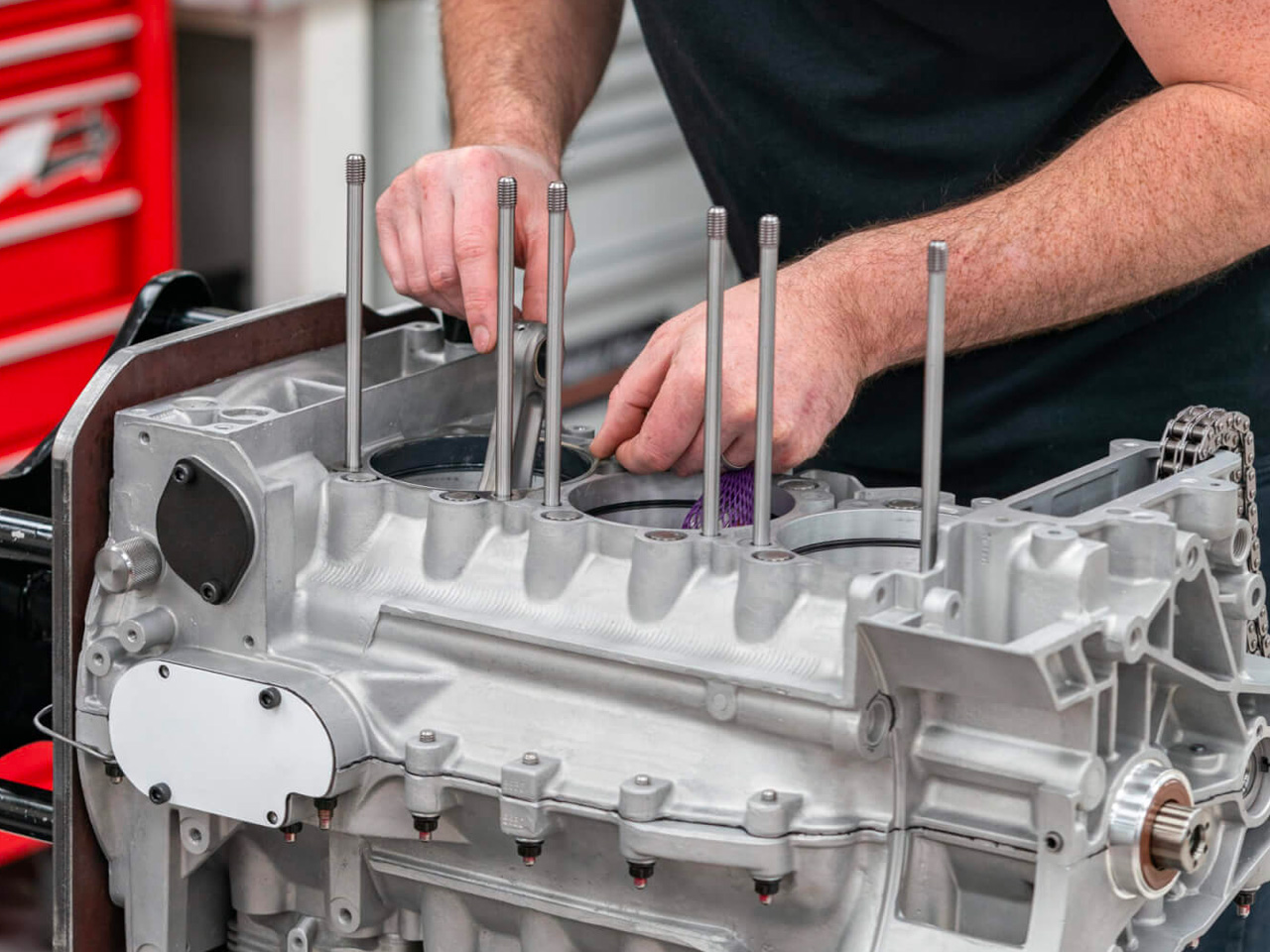

To Singer “everything is important”, and that core ethos lead them to partner directly with the exceptional talents at Nicholson McLaren Engines to produce their flat six cylinder engines for the DLS and DLS Turbo cars in their lineup – where attention to detail is not just a mantra, but is clearly evident in every car they produce.

Nicholson McLaren Engines CEO John Waghorn sat down with ex-racing driver Mike Adams, for the an indepth discussion about this remarkable relationship.

A Q&A with John from Nicholson McLaren Engines

How did your partnership with the iconic Singer brand come about?

Our partnership with Singer was born off the back of a 3 year engine development program where Nicholson McLaren had been intrinsically involved with the design, testing and evaluation of the proto type engines as used in the mule cars.

What projects have you been involved in with Singer?

The DLS product line is our first direct engagement with the Singer brand.

You obviously did a great job on the DLS because you are now involved with Turbo project.

The DLS normally aspirated engine has proven to be a masterpiece of design engineering that delivers on all fronts. The experience gained by Nicholson McLaren’s engineering team in developing the DLS and the transition to the production engine has demonstrated that Nicholson McLaren can achieve the exacting standards required by Singer from their supply partners so it would seem logical that Singer turn to Nicholson McLaren for support in developing the DLS Turbo engine.

OK, and then they stop doing the DLS project?

The current DLS project is approaching run out with all engines on schedule to meet Singers deadline.

How has your relationship developed with Singer and where are you with the turbo project right now?

Through our collaboration we have developed a good working relationship with Singer on DLS that has transitioned to a development program for DLS-T which is on-going.

These are amazing, bespoke engine building projects. How did you determine the spec of the engines between you?

Singer designers provide a brief to the engineering team based on their vision with a specification proposal and then the engineering team have to find solutions that will deliver on that vision. Technically the challenge is extremely complex, compounded by the necessity to package so much technology into an existing body shape and engine bay.

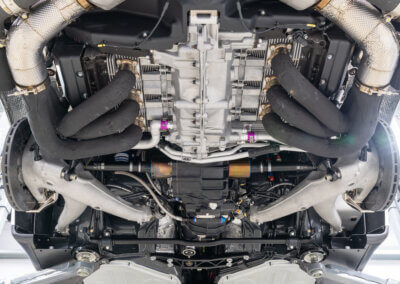

Does that involve aerodynamics underneath, obviously you’ve got to have air coming in?

Cooling the engine to suit various climates around the world is major factor that must be kept in the minds of the engineers, as with the DLS there will be a requirement to draw fresh air into the engine bay from every source possible, no doubt this will include feeding air in via the rear quarter glasses as well as the stylist optimising air flow into the design of the bodywork.

Obviously, there is a synergy and ethos between the two companies. Can you explain where the commonality is?

Both companies strive for excellence. Attention to every detail is absolutely paramount when building engines and when you are presenting a bespoke product to such a high-end client base there is no option – it’s got to be right.

Does that make Singer quite tough on you?

I think that part of the synergy between both companies is that we’re tough on each other!

Nicholson McLaren work in aviation as well. Can you switch all your processes and procedures that you have learnt from aviation straight onto the automotive side?

Nicholson McLaren have taken the ethos of running an Aviation Business and encompassed that into our Automotive Business, in particular this relates to process control, quality & traceability of components. Nicholson McLaren has a zero tolerance policy and all components must be first time fit.

Are Nicholson McLaren looking to complete other bespoke engine building projects with other companies in the near future? Or just concentrating on building their relationship with the iconic Singer brand?

We’re not losing sight of our motorsport heritage, currently have a number of Cosworth and Group C engines on site for rebuilds.

That must be quite a challenge? The company’s shift has been quite significant in a short space of time, so managing your existing customer relationships must be a challenge I guess?

Finding a balance can be challenging so we have to support each client individually in order to meet their expectations.

How has your relationship with Singer changed Nicholson McLaren?

It has made the company more dynamic; we certainly have more people working here now and the mindset is extremely focused.

Does it help you to attract better staff?

We have always had the privilege of attracting good staff, our heritage and working environment together with the high-end product that we look after certainly helps.

John, thanks for sharing the amazing details and insight of this incredible project. We wish both Singer and Nicholson McLaren the very best on future projects and to continuing to develop your wonderful relationship together.

Do you have a question about our race engines? Call us on

Based in Berkshire NME has the facility to design components, build engines, develop existing engines, manufacture and maintain or repair competition race engines from four to twelve cylinders.