UK Non Destructive Testing Specialists

Aviation NDT

AUTOMOTIVE NDT

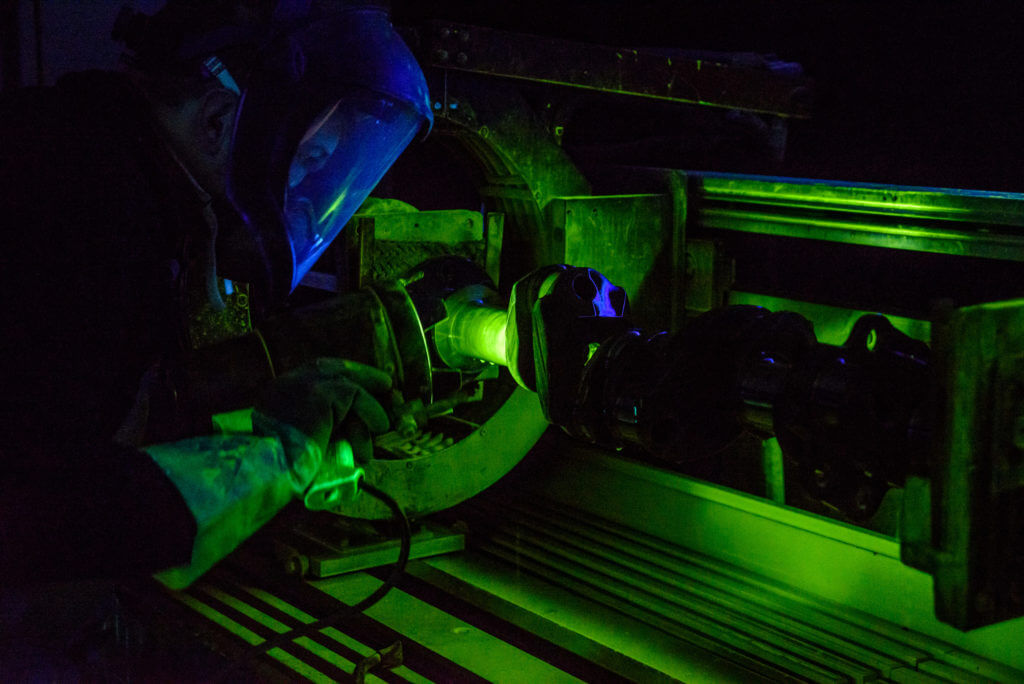

Fluorescent penetrant testing

Nicholson McLaren boasts a purpose built water washable fluorescent dye penetrant line. Whilst generally used to find surface discontinuities in non ferrous components such as castings or aluminium extrusions, ferrous components can also be tested.

It is a cost-effective NDT method that is suitable for individual components or large batches.

Most specifications can be catered for that are based on ASTM standards.

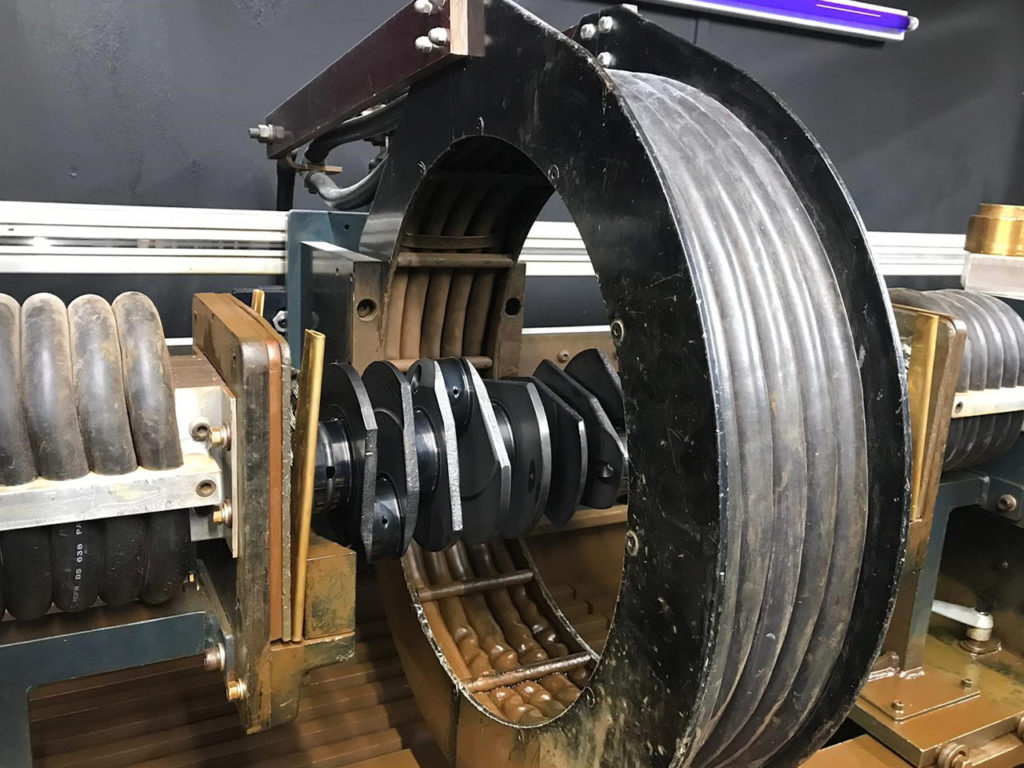

Magnetic Particle Inspection (MPI)

Nicholson McLaren is the proud owner of an 8-foot wet horizontal Magnaflux machine with a large diameter 10 turn coil. This allows the testing of large components without the need for prods or yokes.

It provides a fast repeatable method of testing ferrous components for surface and sub surface discontinuities that might lead to the ultimate failure of the part. Once again most specifications can be catered for that are based on ASTM standards.

Ultrasonic Inspection (MSB96-10)

We have a GE’s Krautkramer USM 36 is the latest development in GE’s USM range of flaw detectors. It combines the 21st century operating platform with the reliable and robust hardware of GE’s well-established Krautkramer portable flaw detection instruments.

COMPLIANCE: At the next and each subsequent removal of the crankshaft from the crankcase for inspection or overhaul, the crankshaft must be ultrasonically inspected by a “qualified inspector” as mandated by this Mandatory Service Bulletin.

Are you looking specialist NDT services? Call us on:

Speak to us about non destructive testing – NDT or would like to know more about our precision engineering capabilities, please phone us today.